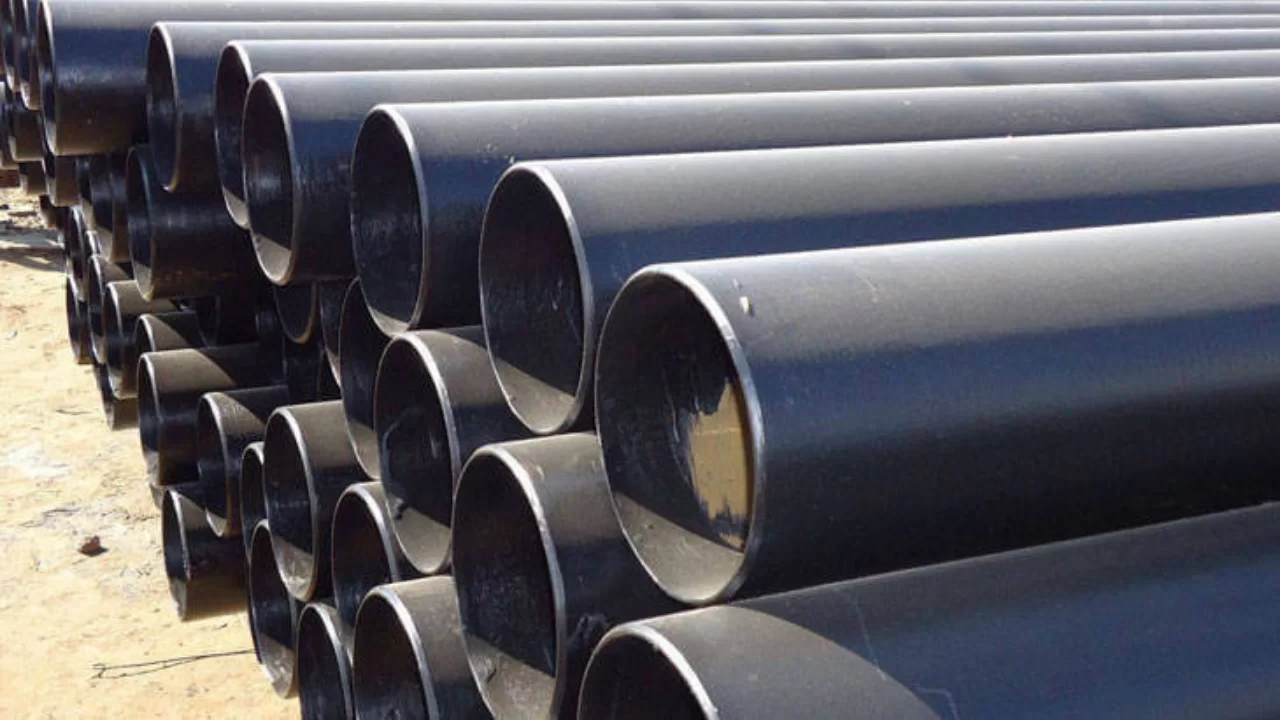

In today’s modern industries, seamless pipes and fittings have become essential due to their high reliability, safety, and long-term performance. This article explores why these components are so widely used across various sectors.

🔧 Key Benefits of Seamless Pipes & Fittings

1. Exceptional Strength & Durability

Seamless pipes and fittings are free from welds, giving them a uniform structure that can withstand high pressure and temperature. This makes them less prone to failure and ensures a longer service life.

2. Corrosion Resistance

Made from materials like stainless steel and alloy steel, seamless products offer excellent corrosion resistance, making them ideal for chemical, marine, and offshore environments.

3. Smooth Flow of Fluids

The smooth inner surface of seamless pipes ensures efficient flow, reduces friction, and prevents sediment buildup—crucial in oil, gas, and water systems.

4. Low Maintenance

Because of their robust construction, seamless pipes require less frequent maintenance, lowering overall operational costs and boosting efficiency.

🏭 Applications Across Key Industries

Seamless pipes and fittings are trusted in industries like:

- Oil & Gas

- Petrochemical & Chemical Processing

- Power Generation

- Construction

- Pharmaceutical

- Food & Beverage

Their ability to perform under extreme conditions makes them the go-to choice for critical systems.

✅ Conclusion

Seamless pipes and fittings provide industries with the strength, safety, and performance they need. From preventing leaks to maximizing efficiency, their advantages make them indispensable in any industrial pipeline setup.